We are Market Leader in Plastic Welding and Process Heat. Since 1949.

The Leister product offering for plastic welding includes hot-air hand tools, extruders and welding machines, including a wide range of accessories for DIY and Industrial markets. In addition to the Leister brand, Leister Technologies AG also sells equipment under the WELDY brand name, which is also available as a private label.

Thanks to our more than 70 years of experience, we offer products and services that set standards in your respective fields of expertise. Whether you use Leister welding equipment for floor installations, roofing, landfills, tunnels, aquatics or other, you can rely on the innovative, durable and efficient Leister plastic welding products.

Leister, along with our more than 80 distributors, are nearby all over the world. We support your plastic welding needs in multiple applications: From flooring and roofing, to geomembranes, plastic fabrication and much more.

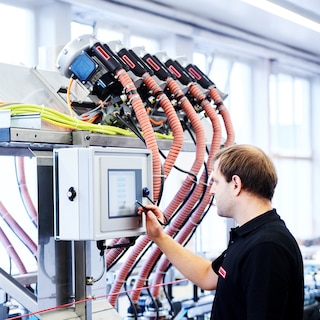

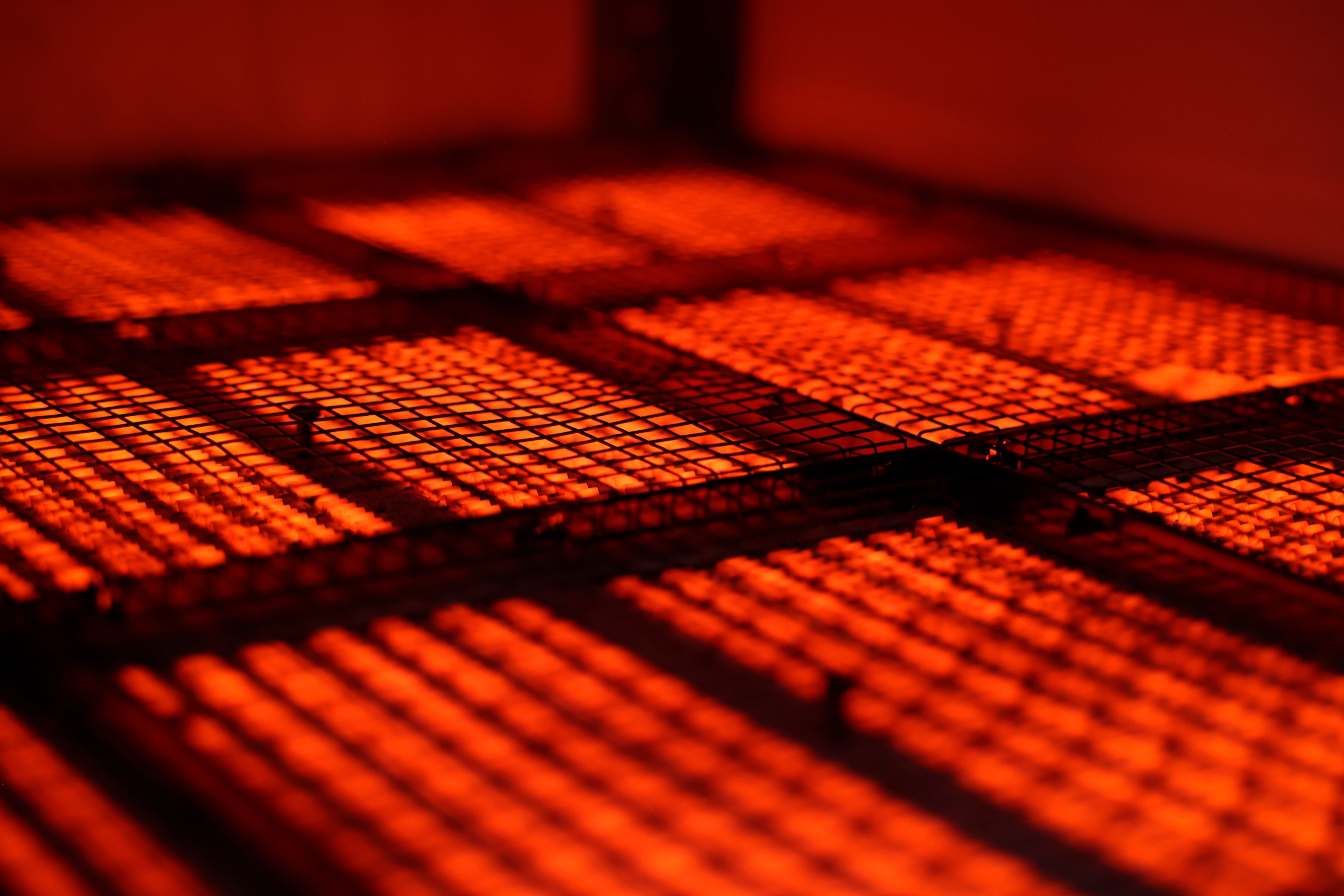

Leister offers solutions with three different technologies for the industrial market: Hot air, infrared and laser. We cover a large part of industrial process heat applications and plastic joining applications.

Thanks to our more than 70 years of experience and wide range of products, Leister offers the right heat source for your specific needs. Our specialists from the Industrial Heating, Infrared and Laser Systems departments have the appropriate knowledge for your production process. In addition to various, standard products such as blowers, infrared modules and laser optics, you can also obtain customized solutions from us. Thanks to our worldwide network, Leister has an extensive service offering for industrial customers from application testing to product support.